The Significance of SPC Calendars: A Comprehensive Guide to Effective Process Control

Related Articles: The Significance of SPC Calendars: A Comprehensive Guide to Effective Process Control

Introduction

With great pleasure, we will explore the intriguing topic related to The Significance of SPC Calendars: A Comprehensive Guide to Effective Process Control. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Significance of SPC Calendars: A Comprehensive Guide to Effective Process Control

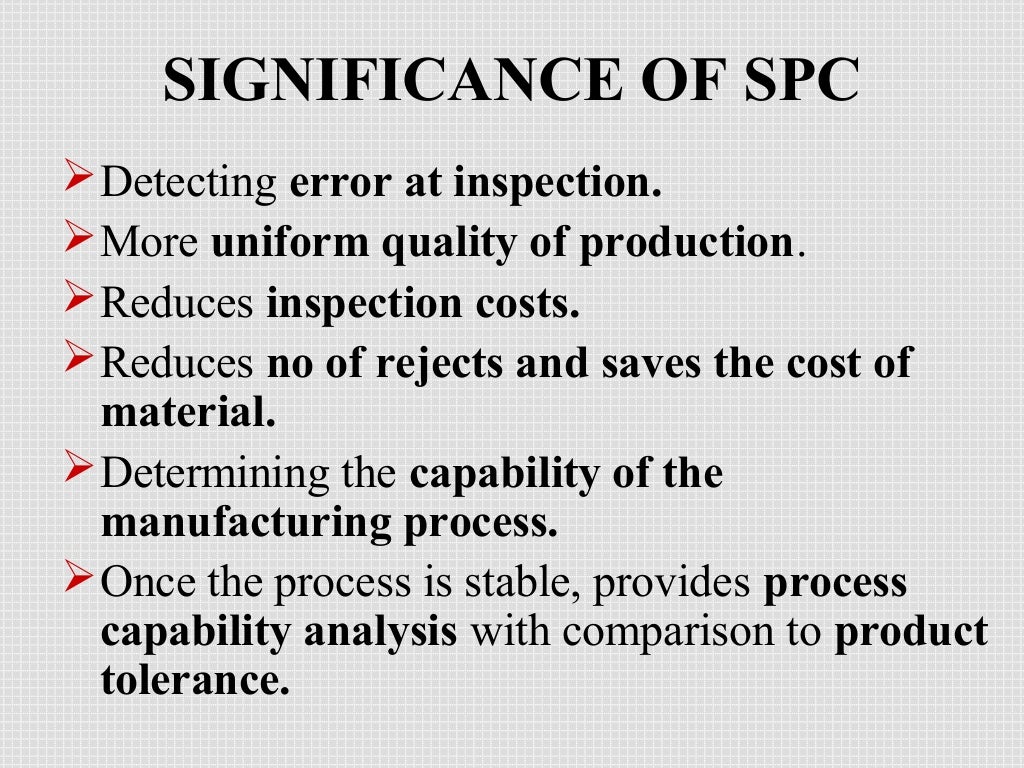

The concept of Statistical Process Control (SPC) has revolutionized manufacturing and quality management. At its core, SPC utilizes data analysis to identify and address process variations, ultimately leading to consistent product quality and improved efficiency. A crucial tool in this process is the SPC Calendar, a visual representation of data collected over time, providing a clear snapshot of process performance.

Understanding SPC Calendars: A Visual Representation of Process Health

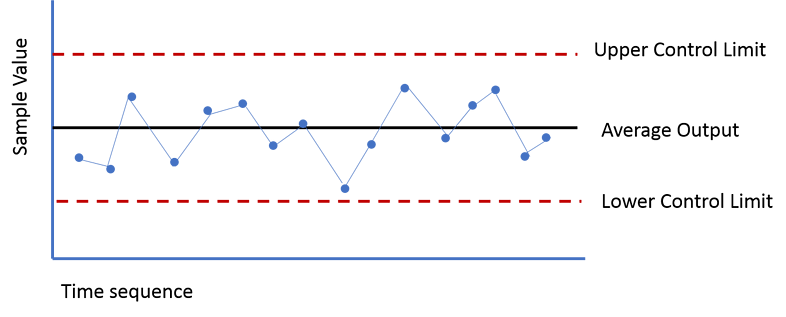

An SPC calendar is essentially a graphical representation of data points collected over a specific period. It typically displays key process parameters, such as measurements of product dimensions, weight, or other relevant quality characteristics. Each data point is plotted on a chart, usually a control chart, which allows for easy identification of trends, patterns, and deviations from expected performance.

Benefits of Implementing SPC Calendars

The use of SPC calendars offers a multitude of advantages for businesses seeking to improve their manufacturing processes and product quality:

- Early Detection of Problems: By visually tracking data over time, SPC calendars enable the identification of potential issues before they escalate into major problems. This proactive approach prevents costly rework, scrap, and customer dissatisfaction.

- Improved Process Control: SPC calendars provide a clear picture of process stability and variation. This allows for targeted interventions to address specific issues, leading to more consistent and predictable product quality.

- Data-Driven Decision Making: The visual representation of data in SPC calendars facilitates informed decision-making. It provides a solid foundation for identifying root causes of process variations and implementing effective corrective actions.

- Enhanced Communication: SPC calendars serve as a powerful communication tool within organizations. They enable different departments, from production to quality control, to share data and insights, fostering collaboration and a shared understanding of process performance.

- Continuous Improvement: The use of SPC calendars fosters a culture of continuous improvement. By regularly monitoring data and identifying areas for improvement, organizations can continuously enhance their processes and product quality.

How to Implement an SPC Calendar

Implementing an effective SPC calendar requires careful planning and execution. Here are some key steps to consider:

- Define Key Process Parameters: Begin by identifying the critical parameters that directly impact product quality. These parameters will form the basis of your SPC calendar.

- Establish Control Limits: Determine the acceptable range of variation for each key parameter. These control limits will be used to assess process stability and identify deviations.

- Collect Data Regularly: Implement a system for collecting data on the defined parameters at regular intervals. This data will be used to populate your SPC calendar.

- Select the Right Chart Type: Choose the appropriate control chart type for each parameter. Different chart types are designed to effectively visualize different types of data and variations.

- Analyze Data and Interpret Results: Regularly analyze the data displayed on your SPC calendar to identify trends, patterns, and deviations from expected performance.

- Take Corrective Action: When deviations are identified, take appropriate corrective actions to address the root cause of the variation. This might involve adjusting process parameters, improving training, or implementing new quality control measures.

FAQs about SPC Calendars

Q: What are the different types of control charts used in SPC calendars?

A: There are numerous types of control charts, each designed for specific data types and applications. Some common types include:

- X-bar and R chart: Used for monitoring the average and range of a process.

- Individuals and Moving Range (I-MR) Chart: Used for monitoring individual measurements and the range between successive measurements.

- p-chart: Used for monitoring the proportion of defective items in a sample.

- c-chart: Used for monitoring the number of defects in a sample.

Q: How often should data be collected for an SPC calendar?

A: The frequency of data collection depends on the specific process and the desired level of control. Generally, data should be collected frequently enough to detect significant variations in the process.

Q: Who should be responsible for maintaining and interpreting SPC calendars?

A: Ideally, a dedicated team responsible for quality control should be tasked with maintaining and interpreting SPC calendars. However, the responsibility can be shared across different departments, depending on the organizational structure.

Q: What are some common mistakes to avoid when implementing SPC calendars?

A: Some common mistakes to avoid include:

- Not collecting enough data: Insufficient data points can lead to inaccurate conclusions and ineffective interventions.

- Ignoring outliers: Outliers may indicate significant process deviations and should be investigated thoroughly.

- Failing to take corrective action: Identifying problems without taking corrective action will not lead to improvement.

- Using the wrong chart type: Selecting the incorrect chart type can misrepresent data and lead to misleading conclusions.

Tips for Effective SPC Calendar Implementation

- Ensure data accuracy: The effectiveness of an SPC calendar relies on accurate data collection. Implement robust data entry systems and regularly verify data for accuracy.

- Involve all stakeholders: Engage relevant departments and individuals in the implementation process to ensure buy-in and effective communication.

- Provide training: Ensure that all personnel involved in data collection, analysis, and interpretation of SPC calendars are properly trained.

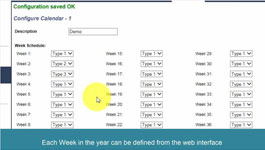

- Use software tools: Utilize specialized software tools for data collection, analysis, and visualization to streamline the process and improve efficiency.

- Continuously review and improve: Regularly review the effectiveness of your SPC calendar and make necessary adjustments to optimize its performance.

Conclusion

SPC calendars are a powerful tool for organizations seeking to improve product quality and process efficiency. By providing a visual representation of process performance over time, SPC calendars enable early detection of problems, informed decision-making, and a culture of continuous improvement. Implementing an effective SPC calendar requires careful planning, data accuracy, and a commitment to continuous improvement. By embracing this approach, organizations can achieve significant gains in product quality, process control, and overall business performance.

Closure

Thus, we hope this article has provided valuable insights into The Significance of SPC Calendars: A Comprehensive Guide to Effective Process Control. We hope you find this article informative and beneficial. See you in our next article!