The MRA Calendar: A Comprehensive Guide to Effective Maintenance Planning

Related Articles: The MRA Calendar: A Comprehensive Guide to Effective Maintenance Planning

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The MRA Calendar: A Comprehensive Guide to Effective Maintenance Planning. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The MRA Calendar: A Comprehensive Guide to Effective Maintenance Planning

- 2 Introduction

- 3 The MRA Calendar: A Comprehensive Guide to Effective Maintenance Planning

- 3.1 Understanding the MRA Calendar: A Blueprint for Asset Health

- 3.2 The Advantages of Implementing an MRA Calendar

- 3.3 Key Considerations for Building an Effective MRA Calendar

- 3.4 Frequently Asked Questions Regarding the MRA Calendar

- 3.5 Tips for Creating and Implementing a Successful MRA Calendar

- 3.6 Conclusion: Embracing the MRA Calendar for Operational Excellence

- 4 Closure

The MRA Calendar: A Comprehensive Guide to Effective Maintenance Planning

The MRA calendar, or Maintenance, Repair, and Overhaul calendar, stands as a cornerstone of operational efficiency and asset longevity in various industries. This meticulously crafted schedule outlines a comprehensive plan for preventive maintenance, repair, and overhaul activities, ensuring that equipment and machinery function optimally and minimize downtime. This article delves into the intricacies of the MRA calendar, elucidating its purpose, benefits, and key considerations for successful implementation.

Understanding the MRA Calendar: A Blueprint for Asset Health

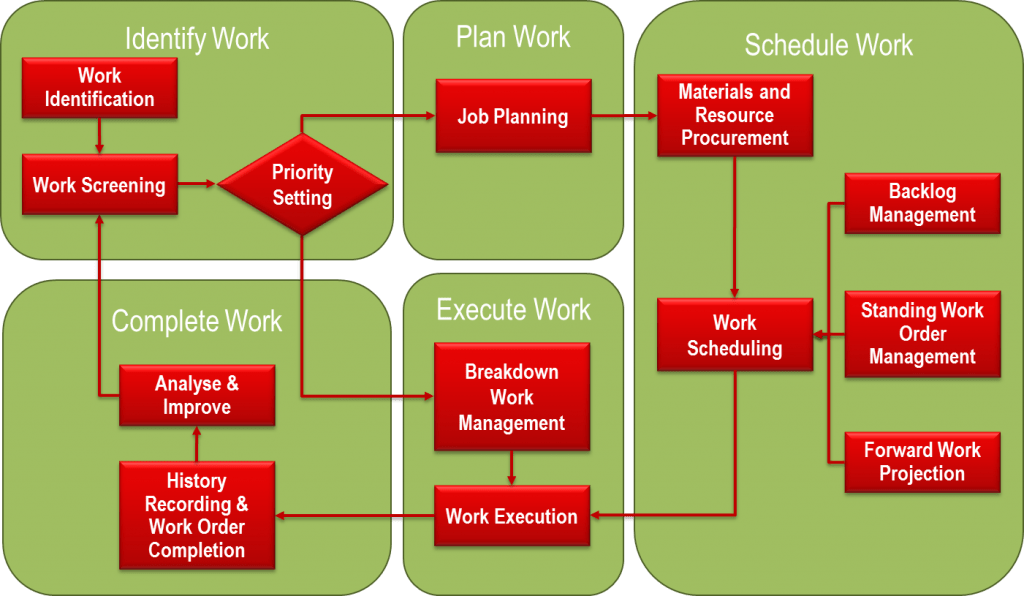

The MRA calendar operates as a detailed roadmap, guiding maintenance teams through a structured approach to asset management. It encompasses the following key elements:

- Preventive Maintenance: This proactive strategy involves regular inspections, lubrication, cleaning, and adjustments to prevent potential failures and extend the lifespan of assets. The calendar outlines specific tasks, frequencies, and resources needed for each piece of equipment.

- Corrective Maintenance: When equipment malfunctions, corrective maintenance steps in to restore functionality. The MRA calendar anticipates potential failures and outlines procedures for prompt repair, minimizing downtime and production disruption.

- Overhaul: This comprehensive maintenance approach involves a thorough inspection, repair, and replacement of worn-out components. Overhauls are typically scheduled at predetermined intervals to ensure the long-term reliability and performance of critical equipment.

The Advantages of Implementing an MRA Calendar

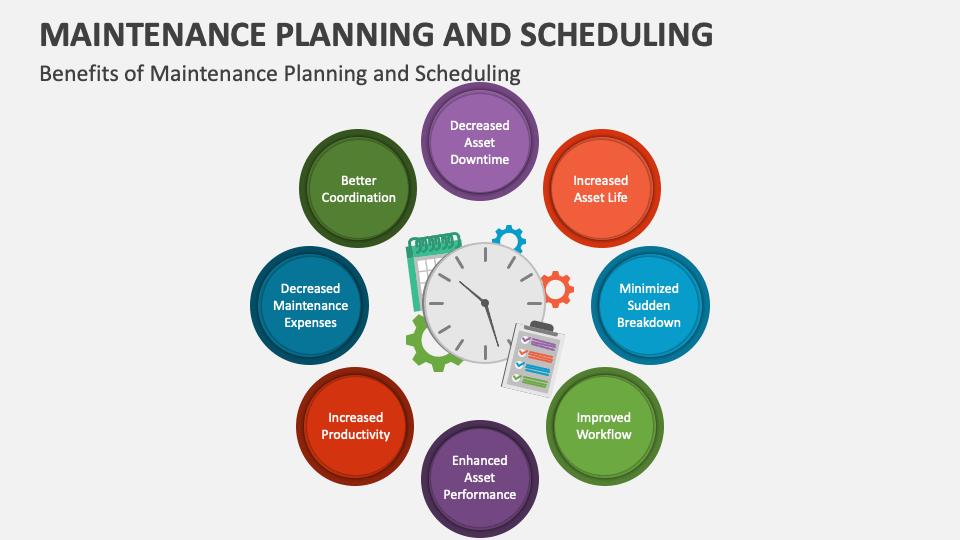

The adoption of an MRA calendar offers numerous advantages, significantly impacting operational efficiency, cost savings, and overall asset health:

- Reduced Downtime: Proactive maintenance and scheduled repairs minimize unexpected breakdowns, ensuring uninterrupted production and minimizing downtime costs.

- Increased Asset Lifespan: Regular maintenance extends the operational life of equipment, reducing the need for premature replacements and associated capital expenditure.

- Improved Safety: Regular inspections and preventative maintenance identify potential safety hazards, reducing the risk of accidents and injuries.

- Enhanced Efficiency: A well-structured MRA calendar optimizes resource allocation, ensuring that maintenance tasks are completed efficiently and effectively.

- Cost Savings: The proactive approach of the MRA calendar helps avoid costly emergency repairs and unplanned downtime, resulting in substantial cost savings over the long term.

- Predictable Maintenance Costs: The calendar provides a clear picture of maintenance expenses, allowing for budgeting and financial planning with greater accuracy.

- Improved Compliance: The MRA calendar can be tailored to meet industry regulations and standards, ensuring compliance and reducing the risk of penalties.

Key Considerations for Building an Effective MRA Calendar

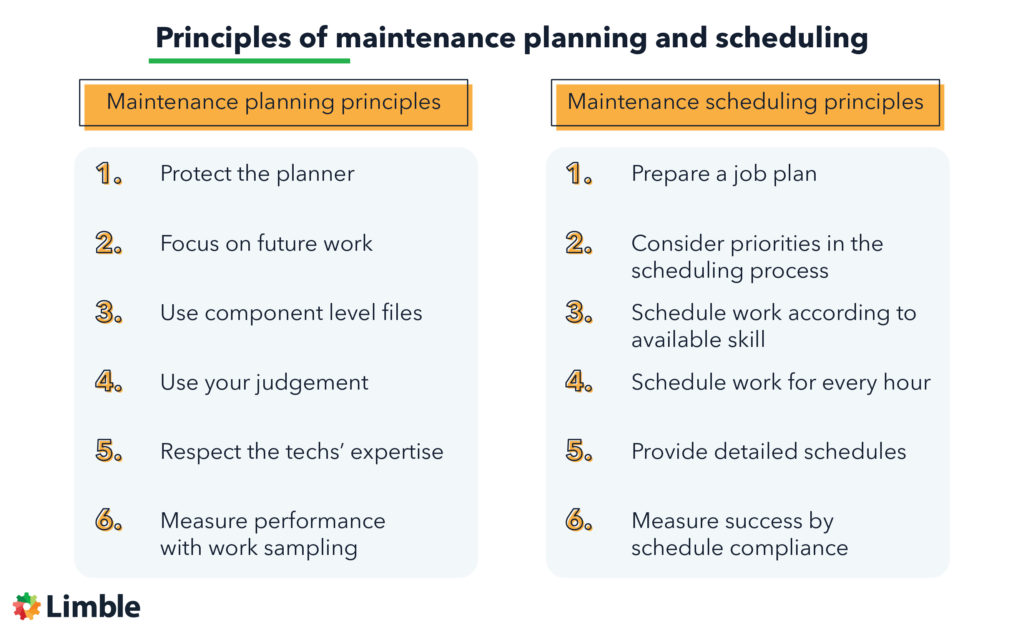

Developing a successful MRA calendar requires meticulous planning and careful consideration of several factors:

- Asset Type and Criticality: Different assets have varying maintenance needs. The calendar should prioritize critical equipment requiring frequent maintenance and allocate resources accordingly.

- Operating Environment: The operating conditions, including temperature, humidity, and workload, significantly influence equipment wear and tear. The calendar should adjust maintenance schedules to reflect these factors.

- Historical Data: Analyzing past maintenance records helps identify patterns and predict future maintenance needs. This data-driven approach ensures a more accurate and effective calendar.

- Maintenance Resources: The calendar should consider the availability of skilled personnel, spare parts, and tools to ensure timely and efficient execution of maintenance tasks.

- Cost-Benefit Analysis: Evaluating the costs associated with each maintenance activity against its benefits ensures that the calendar is optimized for efficiency and cost-effectiveness.

- Flexibility and Adaptability: The MRA calendar should be adaptable to changing conditions, such as new equipment acquisitions, technological advancements, and evolving operating environments.

Frequently Asked Questions Regarding the MRA Calendar

Q: How often should an MRA calendar be reviewed and updated?

A: The frequency of review and update depends on the complexity of the equipment, operating conditions, and industry regulations. A general recommendation is to review the calendar annually and update it as needed based on historical data, equipment performance, and evolving maintenance requirements.

Q: What are the key components of an MRA calendar?

A: An effective MRA calendar should include the following:

- Asset list: A comprehensive inventory of all equipment and machinery subject to the maintenance plan.

- Maintenance tasks: A detailed list of all preventive, corrective, and overhaul tasks for each asset.

- Maintenance schedule: A clearly defined schedule for each maintenance task, including frequency, duration, and resources required.

- Spare parts inventory: A list of necessary spare parts and consumables, their quantities, and their lead times.

- Maintenance history: A record of all past maintenance activities, including dates, tasks performed, and any issues encountered.

Q: How can I ensure that the MRA calendar is effectively implemented?

A: Implementing an MRA calendar effectively requires a combination of planning, communication, and monitoring:

- Clear Communication: Ensure all relevant personnel, including maintenance teams, operations staff, and management, are fully informed about the MRA calendar and its objectives.

- Training: Provide training to maintenance personnel on the specific procedures and tasks outlined in the calendar.

- Regular Monitoring: Track the performance of the MRA calendar, analyze maintenance data, and make adjustments as needed to optimize its effectiveness.

- Feedback Mechanism: Establish a feedback mechanism to gather input from maintenance personnel and operations staff, allowing for continuous improvement and optimization of the calendar.

Tips for Creating and Implementing a Successful MRA Calendar

- Start Simple: Begin with a basic calendar for essential equipment and gradually expand it as you gain experience.

- Utilize Software: Consider using specialized software solutions to streamline the creation, management, and tracking of the MRA calendar.

- Engage Stakeholders: Involve all relevant stakeholders, including maintenance personnel, operations staff, and management, in the development and implementation of the calendar.

- Set Realistic Expectations: Develop a calendar that is practical and achievable, considering available resources and the complexity of maintenance tasks.

- Continuously Improve: Regularly review and update the MRA calendar based on feedback, historical data, and evolving maintenance needs.

Conclusion: Embracing the MRA Calendar for Operational Excellence

The MRA calendar serves as a powerful tool for optimizing asset performance, minimizing downtime, and enhancing operational efficiency. By adopting a structured and proactive approach to maintenance, organizations can significantly reduce maintenance costs, improve safety, and extend the lifespan of their valuable assets. Implementing a comprehensive MRA calendar requires careful planning, effective communication, and ongoing monitoring to ensure its success. By embracing this strategic approach, organizations can achieve operational excellence and unlock the full potential of their assets.

Closure

Thus, we hope this article has provided valuable insights into The MRA Calendar: A Comprehensive Guide to Effective Maintenance Planning. We hope you find this article informative and beneficial. See you in our next article!